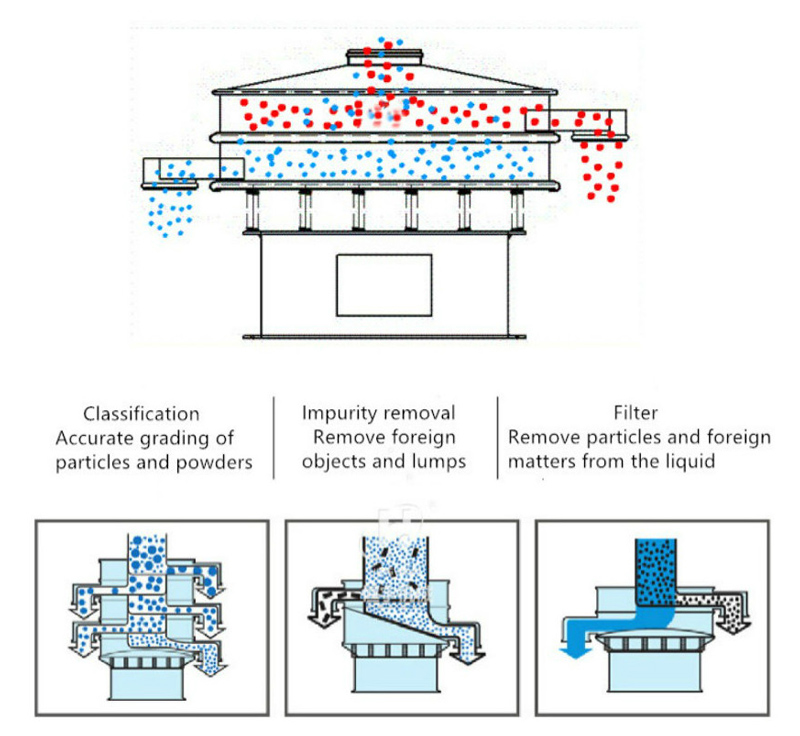

Sifter machine protects the quality of powder or liquid products by removing oversized contaminants, and by adding 1-5 layers of sieves with different mesh numbers, 6 types of grading can be done in one operation.

Diameter: 400mm, 600mm, 800mm, 1000mm, 1200mm, 1500mm, 1800mm, 2000mm

Mesh size: 2-500 mesh

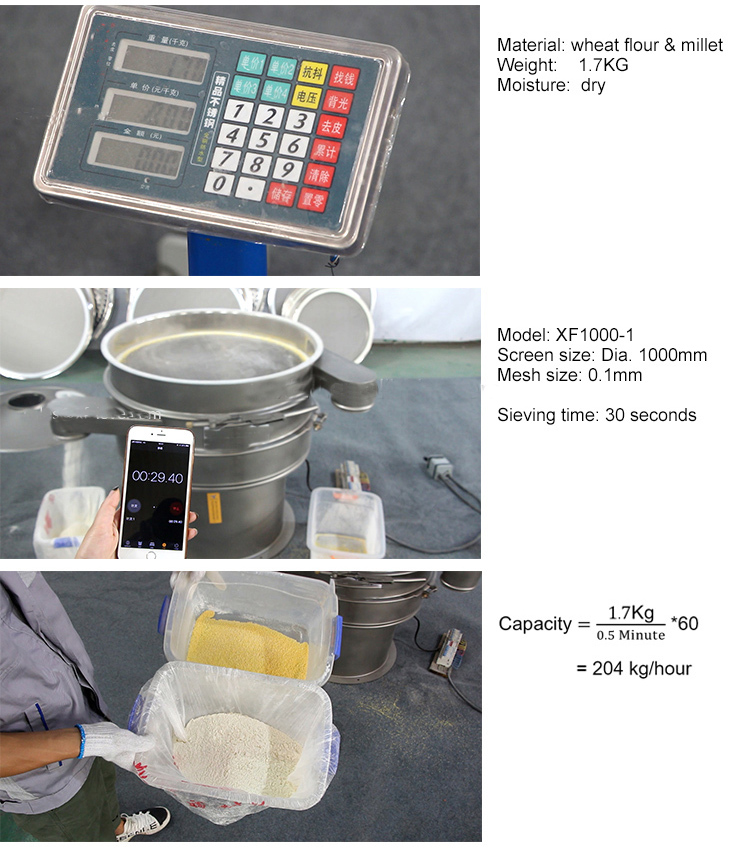

Capacity: 100-3300kg/h

Layer: 1-5

Power: 0.25-3kw

Applications: food, pharmaceuticals, chemicals, coatings, ceramics, metal powders, water treatment, recycling, etc.

Sifter machine is a high precision vibrating screen for inspection and screening of your products, it is very suitable for screening feed ingredients and final production inspection of finished powders, also in the separation process of solids in liquids, separation of different particle sizes of the same product, Safe sieving to remove foreign bodies, particle homogenization, etc.

Made of Q235 carbon steel or SUS304304 stainless steel (or SUS316, on request), it is equipped with a motor with an eccentric mass that produces three-dimensional motion, making product screening as easy as possible, and the adjustment of the mass allows to adjust the behavior of the product in the mesh and sieving speed.

Capable of holding up to 5 sieves and separating up to 6 products, we have several models for all types of production: Ø400, Ø600, Ø800, Ø1000, Ø1200, Ø1500, Ø1800 mm and Ø2000mm, allowing production of 100 to 5,000 kg/ hours, depending on the product, mesh and machine feed flow, and applies to all industries including food, pharmaceutical, additive manufacturing, chemicals, coatings, ceramics, metal powders, water treatment, recycling, and more.

Here are some of the main applications of sifter machine:

1. Remove impurities

This is often one of the first uses of this special processing machine, which removes lumps or growths that form during long-term storage of the material. Such as flour from food processing companies. This happens once you remove the string, insect larvae, tags, and bug debris after packaging or shipping, before you release the product to buyers. Therefore, in an important respect, this special use is very important and necessary to enable the end product to achieve the specified properties.

2. Screening and grading

Refers to the process of separating ingredients by their actual size. According to the principle that solid particles have different settling velocities in the medium due to different particle sizes, the process of classifying particle groups into two or more particle sizes.

3. Scalping

It necessarily involves removing agglomerates or different types of unwanted foreign particles from the more refined material. Some unwanted particles that you can simply get rid of with a scalper may include twigs, tags, strings and sticks, etc. Often, you will find that the mesh or opening size tends to be larger than the actual product size. Thus, skinning can be done simply at the current rate with high material volumes on small screen areas.

Improve your product quality - Eliminate excessive contamination in powders and screen six groups of products with different particle sizes in one use without inconsistent particle size ratios.

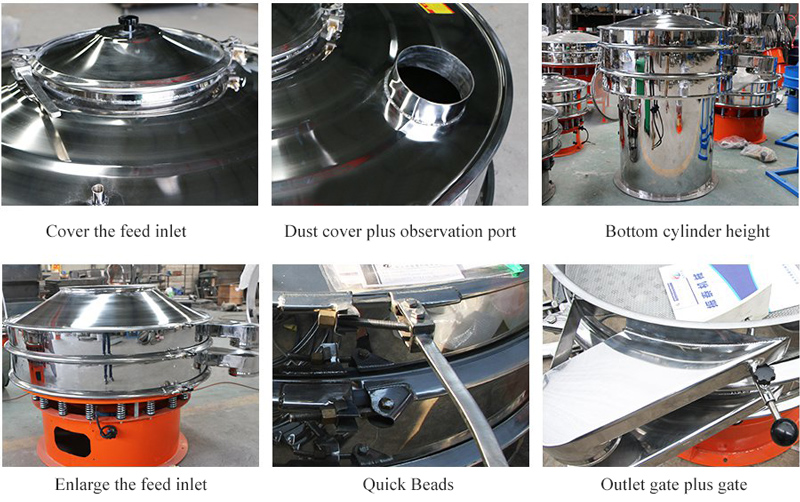

It is not easy to block the screen - there are elastic screen balls under the screen, which can effectively eliminate the blocking holes of the screen and improve the screening efficiency

Automatic discharge - automatic processing of screened impurities and coarse materials, saving labor, after screening, you can enter the next round of screening work by yourself, continuous operation.

Dust Free - The clamping system securely seals the screen, preventing product leakage and also protects the operator from harmful dust

Reduced cleaning downtime - the unit can be easily disassembled without tools and all contact parts are fully washable.

Long-term use - The mesh frame design screen can be used for a longer time, the screen mesh is reasonably tensioned, and the replacement is easy, only 3-5 minutes.

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

| Material | SUS304 stainless steel: mainly used in medicine, food and other industries, SUS304 high-quality stainless steel features: high temperature resistance, high toughness. | Q235A carbon steel: mainly used in the chemical industry, Q235A carbon steel features: good toughness and plasticity. |

| Grid | Adhesive mesh frame: high cleanliness, the whole mesh frame has no dead angle, the screen is directly bonded to the mesh frame, and the screen wire head and corners are not retained; suitable for the food and pharmaceutical industries. | Sub-mother grid: suitable for materials with large specific gravity and strong elaboration, the screen is easy to replace and difficult, and the cost of screen replacement is low; suitable for chemical and metallurgical industries, etc. |

| Cleaning device | The use of the retaining ring and the pinball is a common cleaning device, which is generally used for 100-200 mesh screens. | Ultrasonic cleaning device: generally used for 400-500 mesh screen, features: high efficiency, good cleaning effect. |

| Seals | Rubber seals: mainly used in the chemical industry, high and low temperature resistance, ozone resistance, good electrical insulation. | Silicone seals: mainly used in the food and pharmaceutical industries, with high adsorption performance and good thermal stability. |

The standard models of Vibrating sifter machines are 400mm, 600mm, 800mm, 1000mm, 1200mm, 1500mm, 1800mm, 2000mm, and can be divided into gate type, edged type, mobile type, explosion-proof type and other types according to the special requirements of the materials to be screened by customers.

The Vibrating sifter machine is suitable for dry or wet screening and classification of powder, granular, fibrous materials or slurries.

Chemical industry: resin, paint, pigment, rubber, carbon black, activated carbon, cosolvent, glue, Yuanming powder, polyethylene powder, quartz sand, etc.

Medicine: Chinese medicine powder, western medicine powder, pharmaceutical raw material powder, etc.

Food: sugar, salt, monosodium glutamate, starch, milk powder, soy milk, rice flour, dehydrated vegetables, fruit juice, yeast liquid, pineapple juice, fish meal, food additives, etc.

Kiln industry: glass, ceramics, porcelain mud, abrasive materials, refractory bricks, kaolin quicklime, mica, alumina, calcium carbonate (heavy), etc.

Metal metallurgy: lead powder, zinc oxide, titanium oxide, foundry sand, diamond powder, aluminum powder, iron powder, various metal powders, etc.

Sieving APIs

An essential part of every API manufacturing process, especially where product quality and integrity are so important, the use of sieves eliminates excessive contamination to ensure ingredients and finished products are in production and used or shipped The previous quality is guaranteed.

Sieving Molybdenum Powder

Designed to revolutionize your molybdenum powder recycling process by using a vacuum to extract the powder from the print bed, then sieving the powder for future use, equipped with an ultrasonic deblinding system that transmits ultrasonic frequencies to the screen, allowing fine sieving to 20 microns/500 mesh without clogging the mesh.

Filtered Coconut Milk

The screen removes more bulky pulp from the coconut milk, and also removes solid particles and suspended matter from the coconut milk, which creates a smoother texture and improved quality for the coconut milk.