Vibratory sifter screen is used to sieve feed ingredients and final production inspection of finished powder, eliminate over-contamination in powder, use customized layered screen and powerful 3D vibrating motion to screen product through different screens, just need Continuous filtration of up to 5 levels of product separation in 1 operation.

Diameter: 400-2000mm

Feed particle size: 10-20mm

Mesh size: 2-500 mesh

Capacity: 100-3300kg/h

Power (kw): 0.25-3kw

Vibratory sifter screen is ideal for classification and separation of dry powders, granules and semi-solids/liquids. The material falls on the screen through the inlet at the top, the particles smaller than the mesh size pass through the screen and fall to the lower layer, and the larger particles stay on the screen surface and are discharged from the discharge port to pass through the screens of different mesh sizes. and 3D vibratory motion to screen products, it can accurately screen, sort, dedust and filter a variety of products and materials, is a versatile solution for solid and liquid screening, and can be fully customized to your application.

The vibratory sifter is available in a variety of sizes, suitable for smaller and larger scale operations from φ400 to φ2000, with a capacity of 100-3300kg/h per hour, and can screen 2-500 mesh materials.

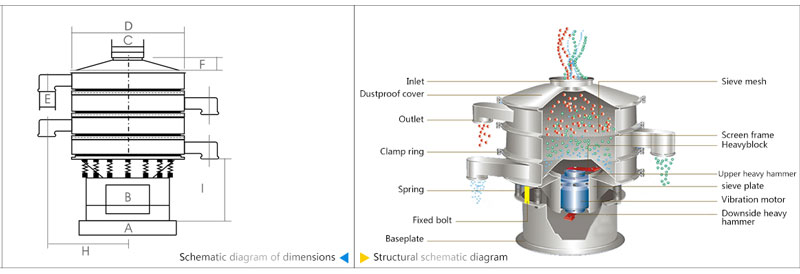

Vibratory Sifter consists of a sieve placed on a base plate which is centrally connected to a rotary motor. The material fed through the inlet located at the top falls on the screen, the particles smaller than the mesh size pass through the screen, and the larger size particles are released through the outlet, which can screen at a faster speed than the standard vibratory sifter The vibratory sifter, the application works on the principle of three-dimensional motion, compared to the traditional vibratory sifter, this vibratory sifter generates 3 times more vibration and provides higher throughput in the ultra-fine screen.

Improves your product quality - Eliminates oversize contamination from your powders

The Vibratory sifter can be fitted with 1 to 4 separation stages, allowing separation of 2 to 5 product fractions.

Reduced cleaning downtime - bouncing ball/ultrasonic cleaning unit prevents clogging of the screen and all contact parts are fully cleanable.

Enclosed system - Enclosed system removing the issue of airborne dust. Contamination-free from a manual interaction.

Small footprint - compact form requires minimal headroom and can easily fit into your existing production line

Reduced noise levels - The rubber suspension system reduces mechanical noise and ensures quiet operation down to 60 decibels.

Vibratory sifter screen is suitable for dry and wet screening and grading of powder, granular, fibrous materials or slurries. It is a new type of high-precision fine particle screening equipment.

Grading and screening: The mixed materials of different particle sizes are continuously selected to become the specification products of different particle size grades.

Screening impurities: high-flow powder material processing, quickly remove large particles or fine powder with little content.

Solid-liquid separation: Quickly remove insoluble solids in various slurries.

Slurry impurity separation: Remove unqualified impurities from the slurry.

Widely used in chemical industry, pharmaceutical powder, liquid, paint, pigment, cosmetics, grease, resin, ceramic slurry, clay slurry, quicklime, refractory powder, metallurgical powder, electromagnetic powder, grinding powder, fruit juice, beverage, sugar, salt, monosodium glutamate , seasoning, milk powder, starch, flour, rice flour, carbon powder, graphite powder, manganese powder, lithium carbonate, co-solvent, fire extinguishing agent and sieving and filtration in the process of sewage and wastewater treatment in the environmental protection industry.

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

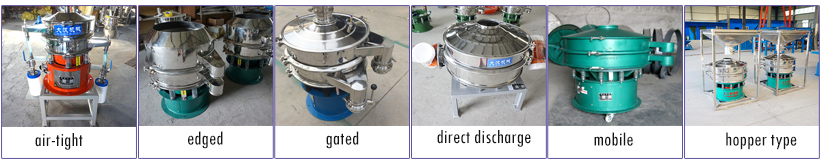

In order to match the raw material characteristics and requirements of individual industries, our vibratory sifter has various types of designs, such as: air-tight / edged / gated / direct discharge / with water spray design or mobile conversion, etc.